The MicroLabBox can be used for the development and validation of control systems across a wide range of applications, including:

- Robotics

- Medical engineering

- Electric drive control

- Renewable energy

- Automotive engineering

- Aerospace

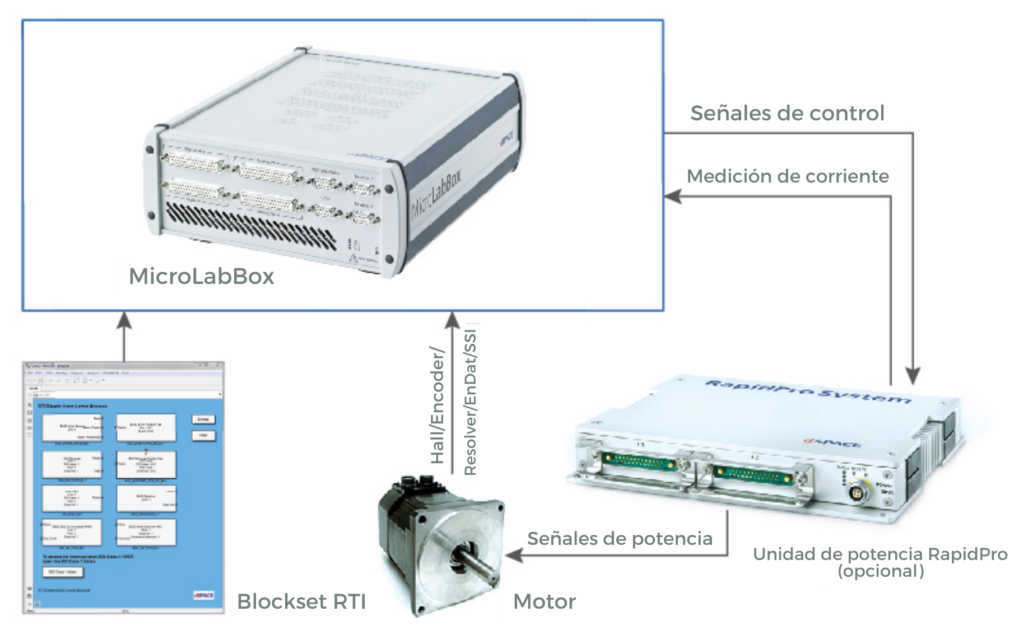

Use Case #1: Development of control strategies for electric motors

MicroLabBox is ideal for developing control functions for various types of electric motors, including asynchronous motors, brushless DC motors (BLDC), and permanent magnet synchronous motors (PMSM). The RTI blockset for electric motor control provides convenient and comprehensive configuration options for I/O interfaces.

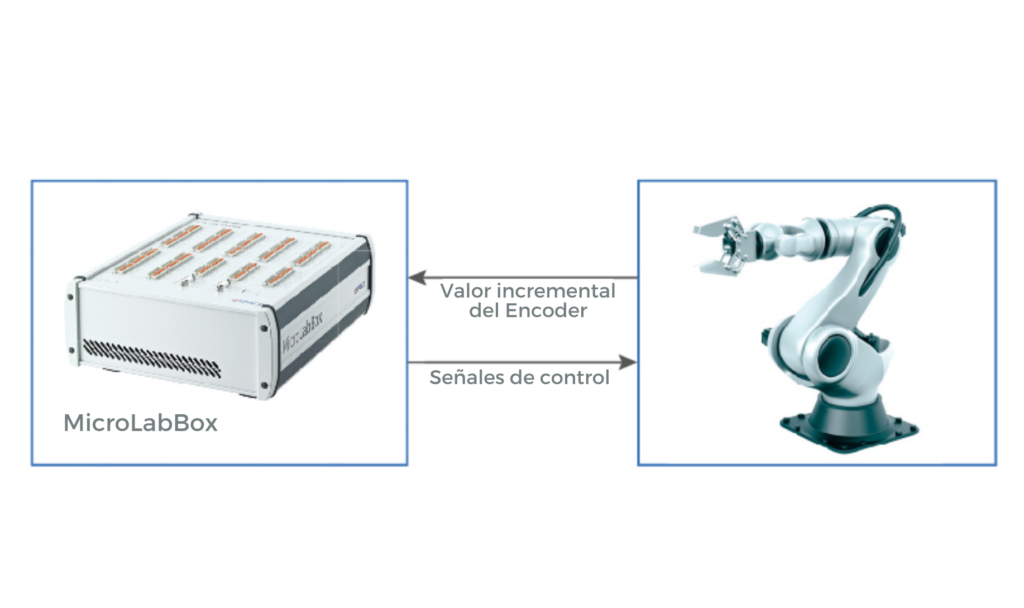

Use Case #2: Rapid control prototyping in robotics

The extensive interfaces of the MicroLabBox make it an ideal solution for various robotic applications. In this example, the MicroLabBox replaces the robot’s position controller, receiving signals from the incremental encoder to determine the robot’s position. The real-time processor then calculates the control algorithm and sends the controller output, including position and speed data, back to the robot. This setup enables rapid implementation and testing of different control algorithms.

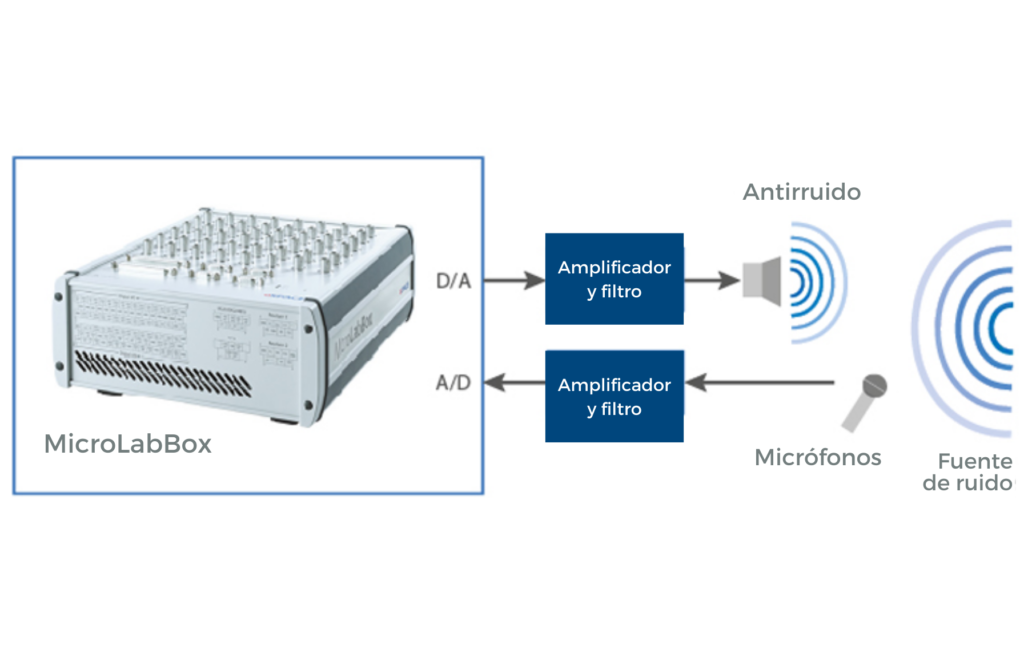

Use Case #3: Active noise cancellation and vibration damping

Applications in active noise cancellation (ANC, e.g., high-fidelity headphones, mobile phones, or passenger cabins) and vibration damping (e.g., to reduce wear or industrial plant noise) present a significant challenge for signal processing. In active noise cancellation applications, for instance, the anti-noise signal must be calculated and generated before the original noise reaches the respective noise-canceling speaker or the designated noise cancellation point in space. The fast real-time processor of the MicroLabBox and its low-latency I/O access make this platform ideal for developing new algorithms for both active noise and vibration reduction. The MicroLabBox achieves control loops in just a few microseconds, and if higher performance is required, algorithms can be offloaded to the integrated FPGA.

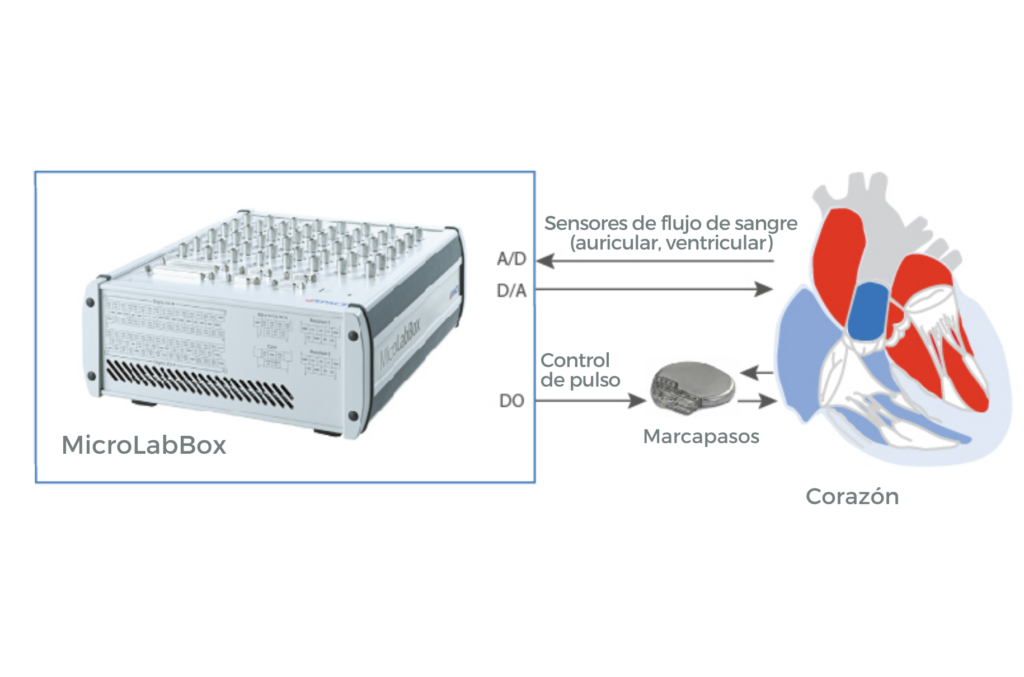

Use Case #4: Development and testing of medical devices

Both safety and reliability are crucial in the development of medical devices, which is why every new function requires optimal design and rigorous testing. Often, capturing and preprocessing signals are integral to function development; with MicroLabBox, you can delegate extensive, computation-heavy signal processing tasks, such as filtering or signal analysis, to the integrated FPGA.

By connecting BNC cables directly to the MicroLabBox to process analog signals, the influence of external errors on the signal is minimized, enabling high signal quality. During and after medical device development, you can use the MicroLabBox as a testing system to reliably simulate various environmental conditions, either based on test algorithms or on existing measurement data. This approach increases the maturity of the medical device, saving time, reducing costs, and minimizing the risks associated with live organism testing.