MicroLabBox

Exciting New Options for Universities

The MicroLabBox is a multi-purpose rapid control prototyping system. It is a compact, all-in-one platform designed specifically for use in a lab environment.

- Compact all-in-one development system for laboratory purposes.

- Dual-core real-time processor at 2 GHz.

- User-programmable FPGA.

- More than 100 channels of high-performance I/O.

- Dedicated electric motor control features.

- Ethernet and CAN bus interfaces.

- Easy I/O access via integrated connector panel.

The MicroLabBox is a multi-purpose rapid control prototyping system. It is a compact, all-in-one platform designed specifically for use in a lab environment.

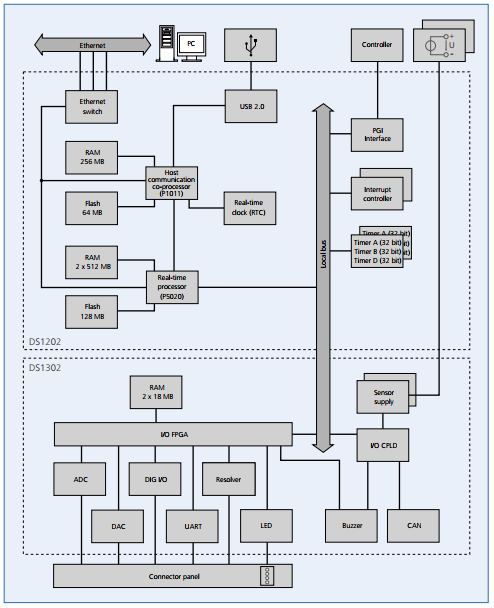

Internally, the MicroLabBox includes the DS1202 baseboard that houses the main, real-time, dual-core processor, and a separate co-processor that manages host PC communications. This is an important feature because every so often, we get questions from our customers about the impact of a lot of host PC data traffic, caused by data capturing, and how it might impact the processing power of the platform.

In the case of the MicroLabBox, the separate host communication processor takes care of the flight recorder capability to capture data, the host interface, and the ethernet I/O so the real-time processor can be dedicated to executing the application model. The MicroLabBox also includes a dedicated USB interface for data logging.

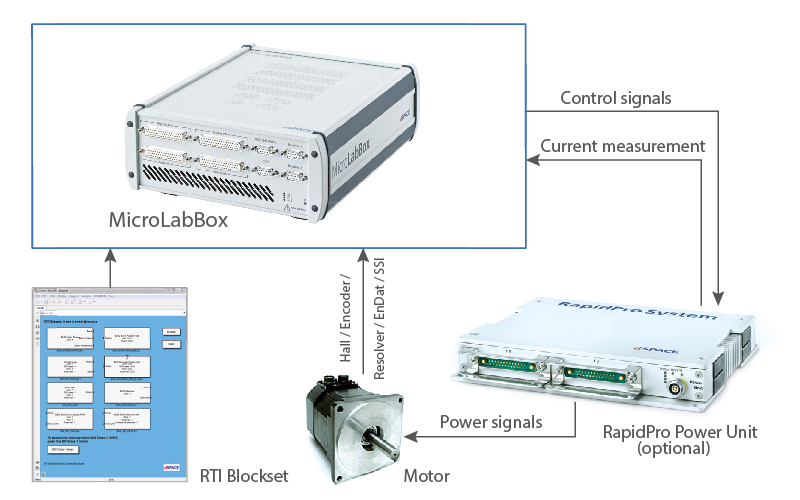

Like all other dSPACE platforms, the MicroLabBox includes a RTI Blockset that allows you to model your control algorithms and access virtually all of the I/O and the capabilities of the MicroLabBox in Simulink. In addition, the C library allows you to use the MicroLabBox for C-coded applications.

The MicroLabBox has powerful computing capabilities. With its dual core processor, the new system boasts speeds of up to 2 GHz. The MicroLabBox can compute models up to 6 times faster than the DS1103 or DS1005, making it our fastest processor yet. This feature is especially beneficial for medium- and large-sized models.

Panel Variants

MicroLabBox, front panel variant

MicroLabBox, top panel variant with BNC connectors

MicroLabBox, top panel variant with sprint-cage terminal blocks

TECHNICAL DETAILS

Application Areas for Mechatronics Research & Development

MicroLabBox can be used for control system development and testing across a very wide spectrum of applications such as:

- Robotics

- Medical Engineering

- Electric Drive Control

- Renewable Energy

- Vehicle Engineering

- Aerospace

Use Case #1: Developing Control Strategies for Electric Motors

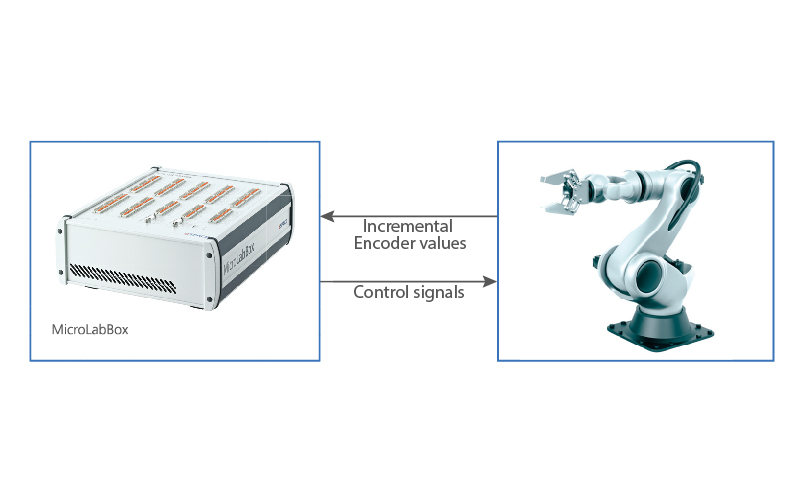

Use Case #2: Rapid Control Prototyping in Robotics

Its numerous interfaces make MicroLabBox ideal for many kinds of robotics applications. In this example, MicroLabBox replaces the robot’s position controller and receives the robot’s incremental encoder signals for determining the current position of the robot. Then, the real-time processor calculates the control algorithm and sends the controller output with position and velocity data back to the robot. Thus, you can implement and test different control algorithms very quickly.

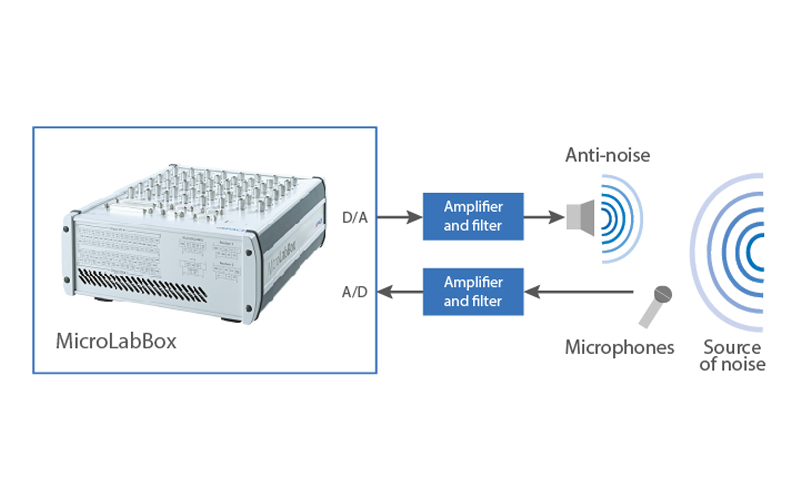

Use Case #3: Active Noise Cancellation and Vibration Damping

Applications in active noise cancellation (ANC: e.g., for hi-fi headphones, cell phones or a passenger car cabin) and vibration damping (e.g., for reducing wear and tear or industrial plant noise) pose a particularly great challenge for signal processing. For ANC applications, for example, the anti-noise has to be calculated and generated before the original noise reaches the respective noise cancellation speaker or the point in space designated for noise cancelling. MicroLabBox’s fast real-time processor and lowla-tency I/O access make it the right tool for developing new algorithms for active noise reduction and vibration reduction. MicroLabBox achieves control loops of only a few microseconds. If the requirements are even higher, the algorithms can always be offloaded to the integrated FPGA.

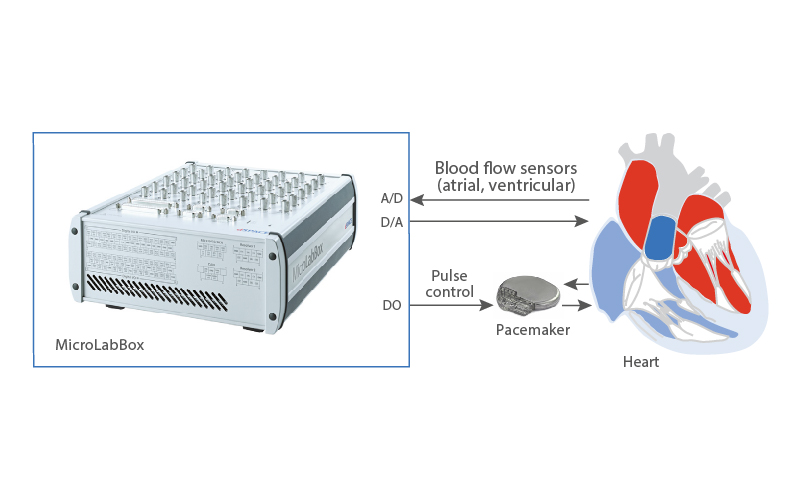

Use Case #4: Developing and Testing Medical Devices

Safety and reliability play a crucial role in the development of medical devices. New functions must have an optimal design and undergo extensive testing. In many cases, capturing and preprocessing signals is an integral part of function development. With MicroLabBox, you can outsource extensive and computation-intensive signal preprocessing tasks, such as filtering or signal analysis, to an integrated FPGA.

Connecting BNC cables directly to MicroLabBox for processing analog signals minimizes the influence of external errors on the signal and makes it possible to achieve a high signal quality. During or after the development of the medical device, MicroLabBox can also be used as a testing system. With it, you can reproducibly simulate many different environment conditions, e.g., based on test algorithms or existing measurement data. This increases the medical device’s maturity, saves time, reduces costs, and minimizes the risks compared to tests on a living organism.